In-house process

In order to ensure quality control, Blue Horizon has integrated vertically in their supply chain to acquire synergies and optimize production processes.

01.Laser cutting

Improving cutting precision through laser Cutting machines

02.Stitching

Automated stitching machinery in order to eliminate variances in product quality and improve productivity

03.packaging

Air tight high quality packaging to ensure product longevity

Safety Tech

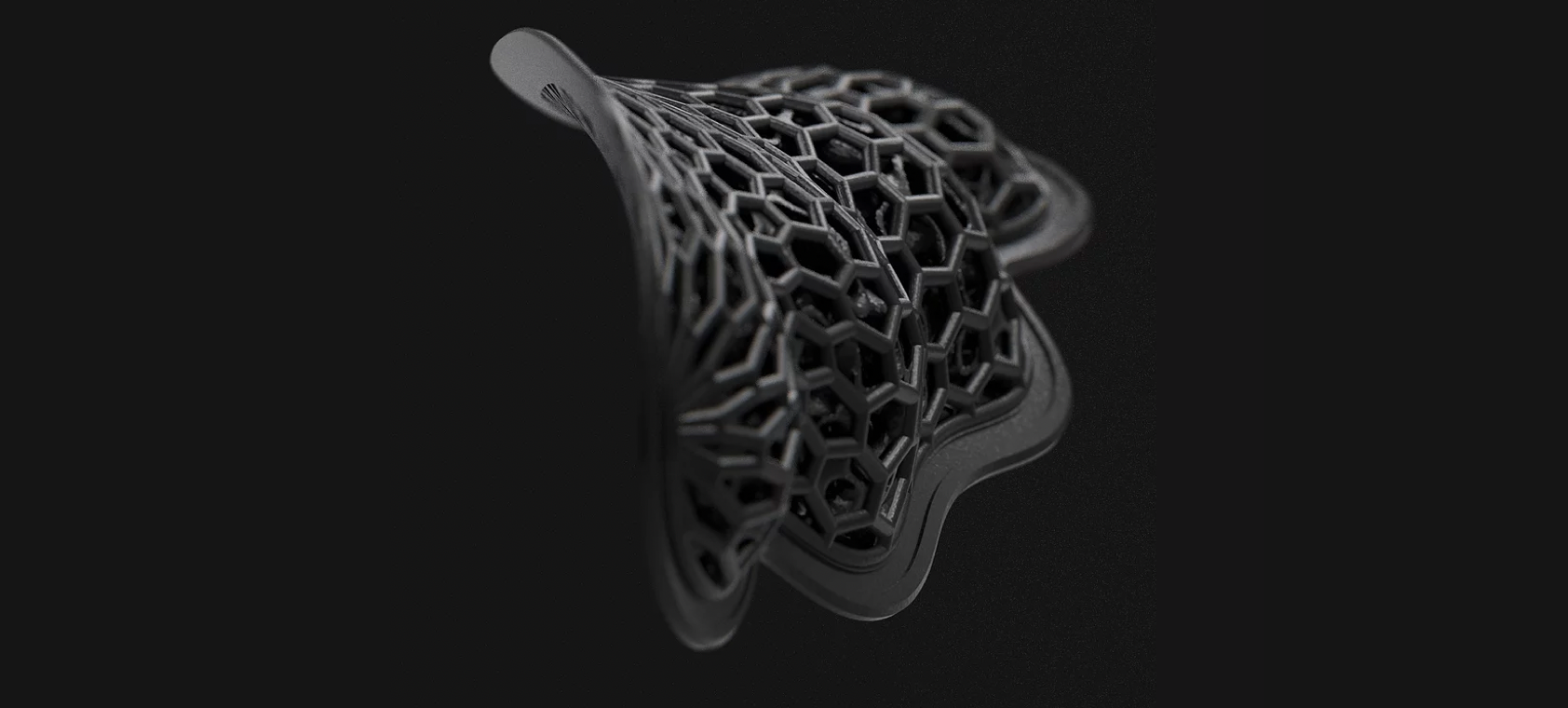

In collaboration with Carbon, we have developed materials that are unbeatable for providing safety. Our materials are made through the process of Digital Light Synthesis. DLS™ is a breakthrough technology that uses digital light projection, oxygen-permeable optics, and programmable liquid resins to produce materials with extraordinary mechanical properties.

Compliance

Lasting Comfort

The open architecture of the lattice allows air to flow through its innovative design, providing breathability and comfort so you can stay focused on the task at hand.

Ultimate Protection

The Carbon DLS™ 3D printing process uses software to automatically generate hundreds of highly optimized lattice designs that meet ANSI Level 3 protection standards. The perfect combination of cell pattern and strut size are combined to achieve the desired mechanical properties and performance criteria.

Flexibility and Control

Carbon’s flexible poly-urethane material formulation is tough enough to absorb energy from dangerous impacts while not limiting the flexibility and control you need to get the job done.

Digital Light Synthesis

Light and oxygen combine to solidify liquid-polymer resins, building a part’s geometry pixel by pixel. A secondary chemical reaction is triggered during a thermal bake, reinforcing the integrity of the part by growing and cross-linking additional polymer chains.

Factory Tour

We welcome you to visit our state of the art manufacturing facility in Vietnam, in the mean while here is an online introduction of our departments.

Comfortable Working Environment

A working environment that encourages harmony among colleagues. We promote teamwork and collective problem solving among departments, through engaging projects and presentations

Cutting Department

Our Cutting process is automated through press machines and laser cutting machines to reduce variance in our products

Sampling Department

Our tailormade sampling development enforces the reflection of our craftsmanship in our sampling developments

Computerized Stitching

Computerized stitching allows us to increase our output and scale our production. Furthermore, it allows us to collect data regarding our output and reduce variances in quality

Sanatorium

We have our in house medical facility that provides free medical check ups and prescriptions to our employees

Cafeteria

Our employees enjoyed a multitude of cuisine offered by our chefs. We also provide customized dishes for individuals with dietary restrictions

Adhering to compliance regulations and procedures within our manufacturing industry is mandatory. We are compliant with European CE and ANSI requirements.